Stone Paint

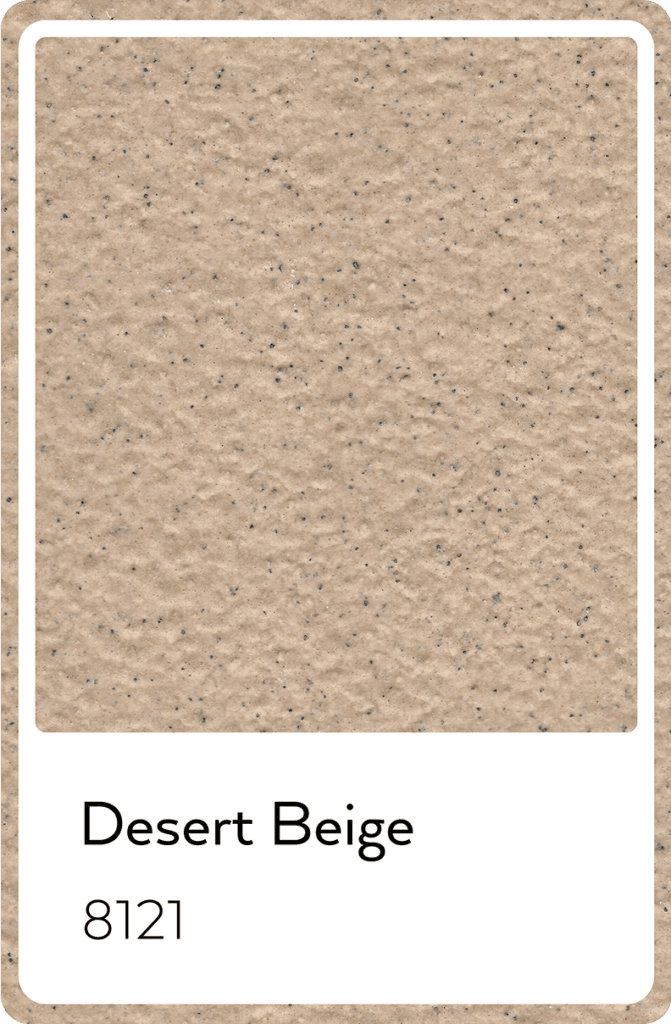

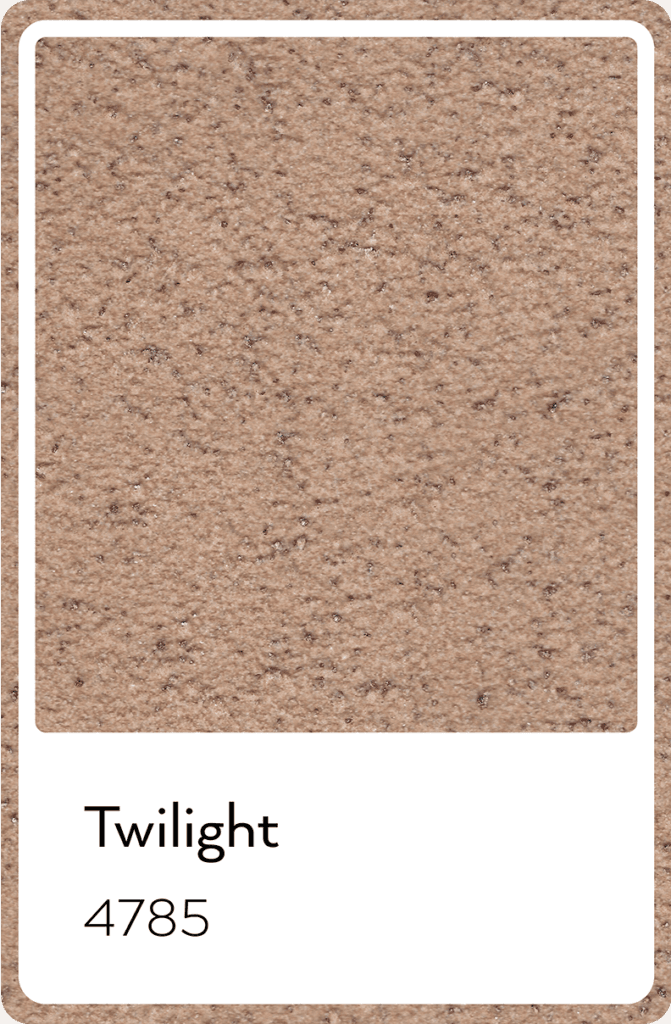

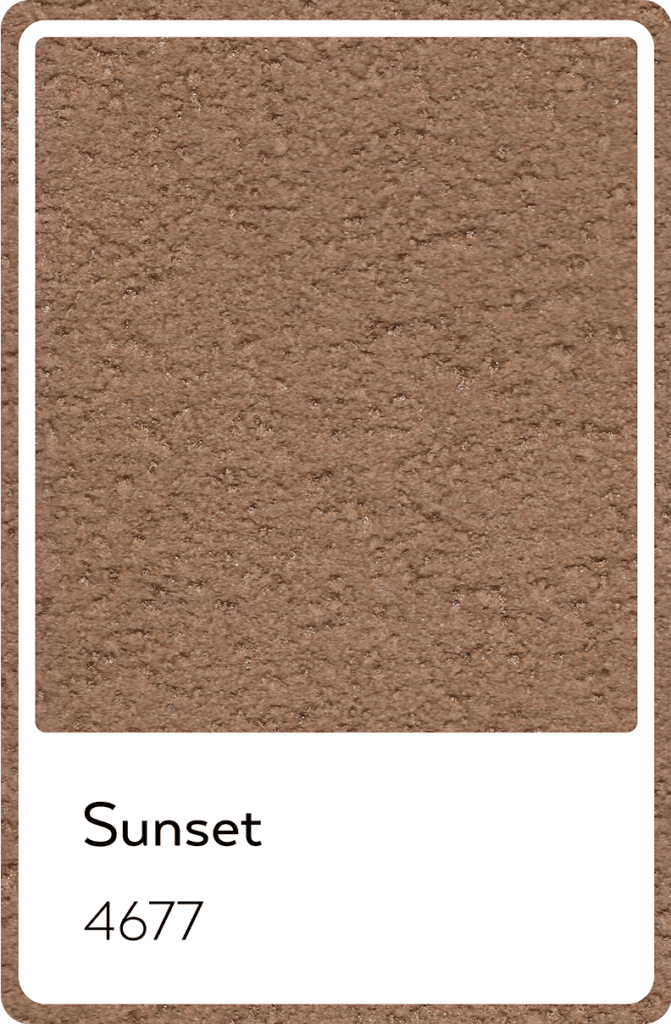

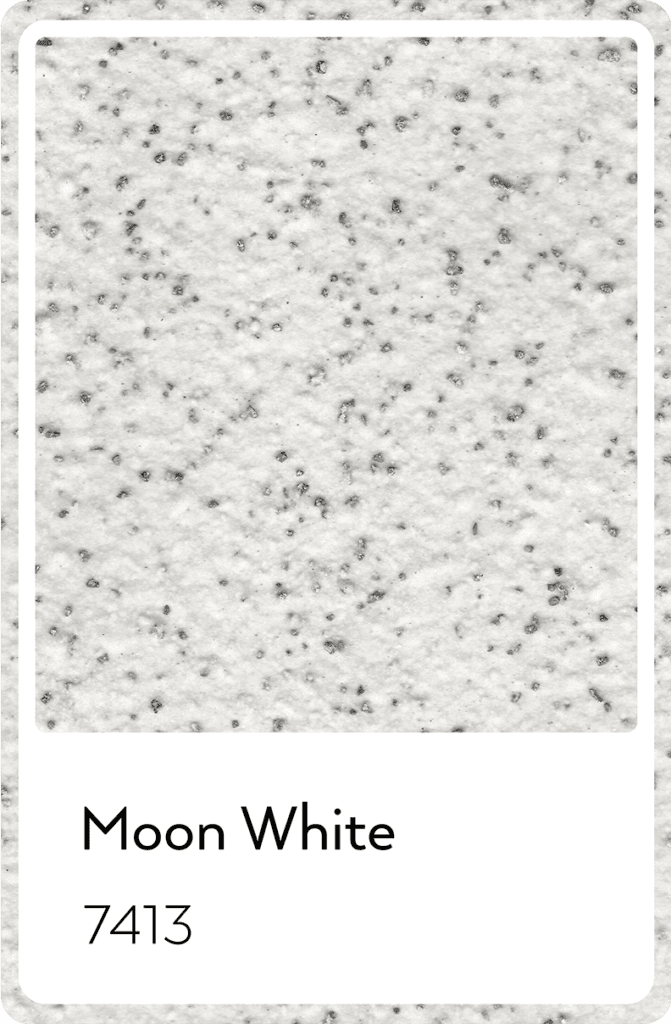

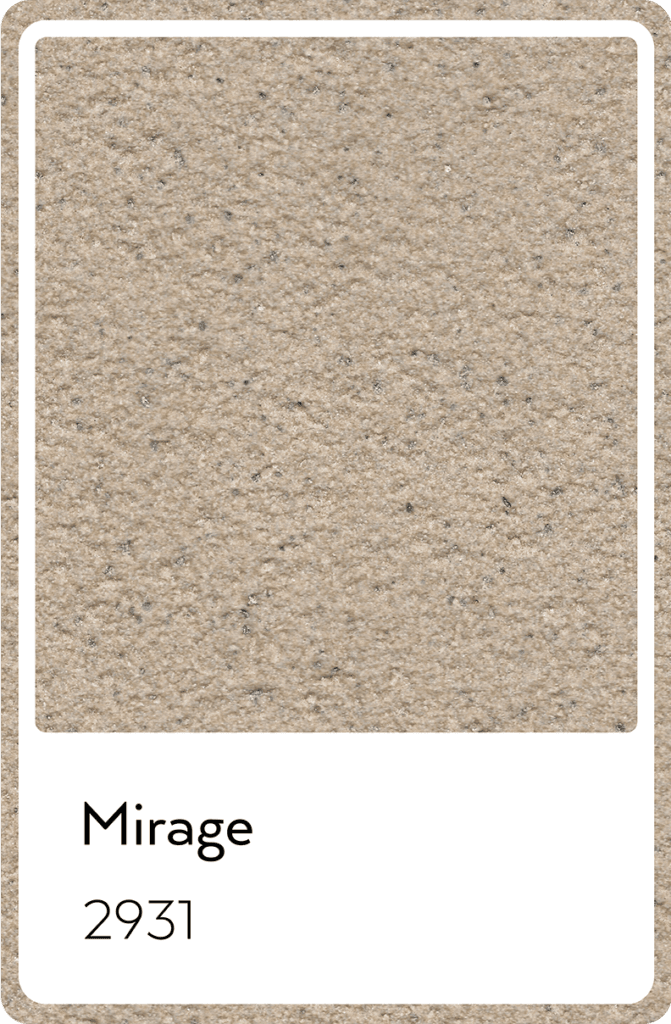

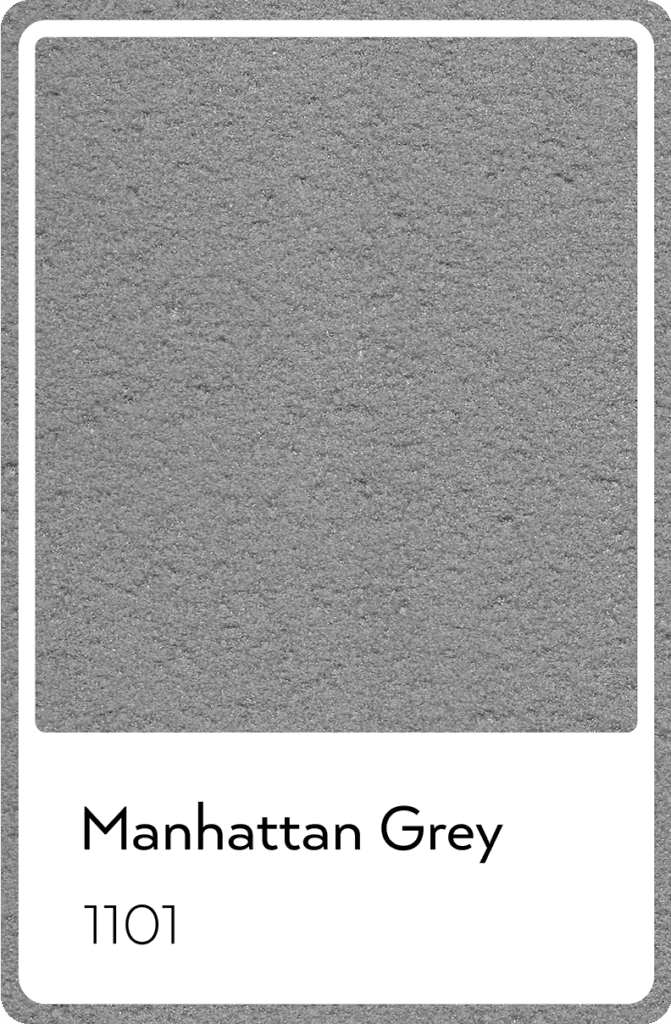

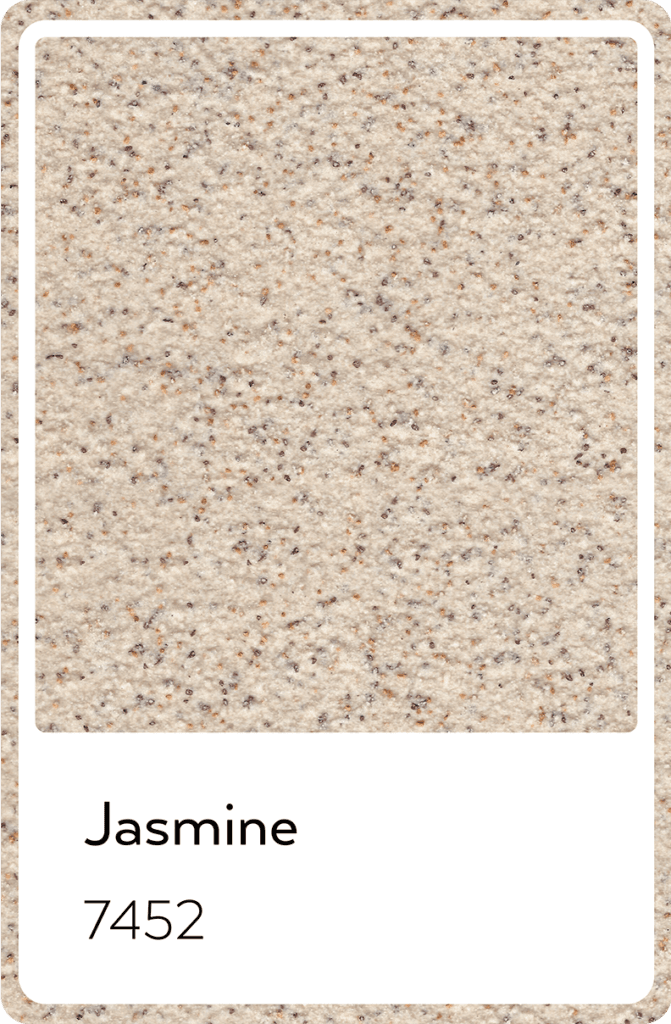

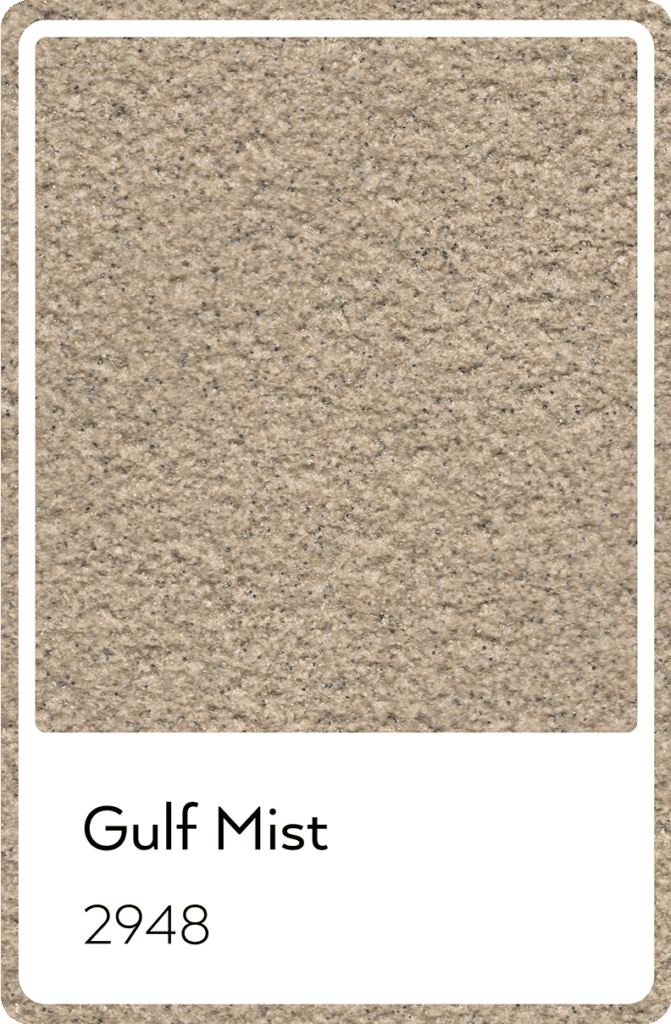

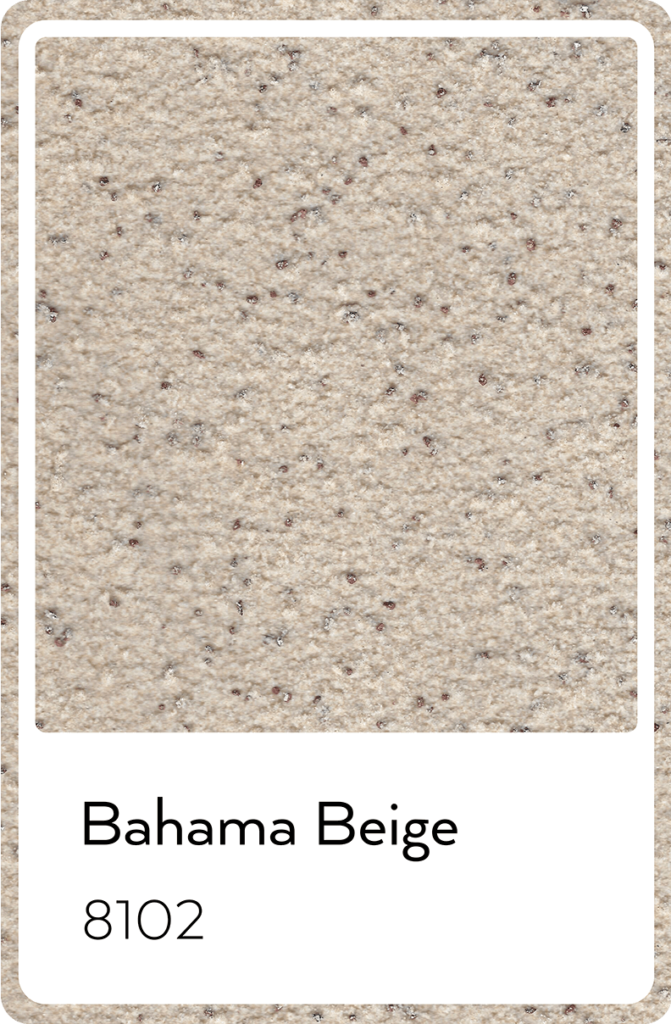

Stone Paint Colors

MARMO Stone Paints

Premium Acrylic-Based Stone Paint with a Semi-Rough Finish

MARMO Stone Paint is a high-quality, water-based coating made from crushed natural marble aggregates bonded with pure acrylic resin. Its natural color is derived from marble without the use of oxides, offering a semi-rough texture ideal for finishing applications.

Key Features

High UV Resistance: Ensures longevity and protection from sunlight.

Superior Resistance to Atmospheric Pollution: Withstands harsh environmental conditions.

Exceptional Durability: Provides long-lasting performance.

Natural Stone Effect: Mimics the texture of natural stone.

Excellent Adhesion: Bonds effectively to various surfaces.

Water-Resistant for Vertical Surfaces: Provides limited water resistance.

Easy Application: Simplifies installation with minimal effort.

Eco-Friendly: Environmentally sustainable product.

Pollutant Resistant: Resists environmental contaminants effectively.

Minimizes Cracks: Reduces surface cracking, lowering maintenance costs.

Lower Maintenance and Recoating Costs: Improves façades durability.

Recommended Applications

Suitable for both interior and exterior use on:

Application Instructions

Surface Preparation

The coating’s performance depends on proper surface preparation:

Mixing

MARMO Paint is a single-component, water-based product.

Application Guidelines

Technical Specifications

Volume Solids: | 82% |

Appearance: | Paste |

Density: | 1.8 kg/Litter |

Flexibility: | High (Tested to ASTM D522) |

Application Temperature: | +5°C up to +40°C |

In-Service Temperature: | -20°C up to +80°C |

Water Resistance: | Excellent |

Colors: | Natural marble shades only |

Consumption: | 1.8 kg/m²/mm thickness |

Finish: | Matte / Semi-Rough |

Coverage: | 3 to 5 kg/m² |

Drying Time: | 18 hours at 35°C |

Touch Dry: | 3 hours |

Packaging: | Available in 23 kg buckets |

Shelf Life: | 24 months when stored properly |